Behind BBTWINS: The Vision, the Tech, and the Journey – Interview with the Coordinator

Daniel de la Puente

Head of EU Projects CNTA

How did BBTWINS use digital technology to innovate the agri-food sector? Read this quick interview with Project Coordinator, Daniel de la Puente who explained the project, its goals and journey.

What inspired the creation of your project?

By 2019 we were already simulating food processes in digital environments. We had replicated high temperature cooking and the effect on different vegetables. In parallel we had developed NIR cameras capable of detecting food fraud powered by artificial intelligence. Then, in 2020, confinement gave us all plenty of time to time outside the lab which sparked the idea of bringing digital twins, artificial vision, blockchain and logistic models together into one single platform for the food industry -BBTWINS. We wanted to create one single point of interaction with the user, so that the multiple interfaces behind wouldn’t be visible, nor the interaction between them. The ultimate digital tool in the cloud for food industries to benefit from digital and green transition technologies. At the end of the day costs need to be as low as possible for prices to be affordable for consumers and still leave profits for businesses. BBTWINS aims to boost efficiency, give transparency to consumers and maintain high product quality standards.

Seeking smarter solutions

Can you share some of the key milestones or successes your project has achieved to date?

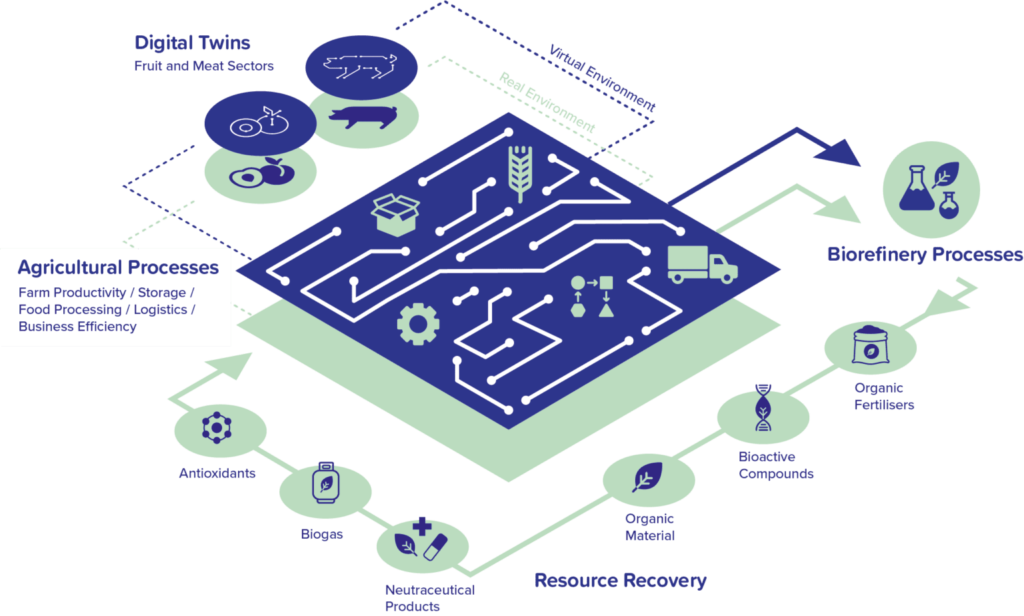

We have achieved the full sensorization of two value chains, pork and fruit. We have developed and validated predictive models for pork weight, backfat thickness, and fruit yield forecasting onsite at the orchards using artificial vision. We have identified and defined waste streams for optimization, explored advanced technologies for feedstock processing, developed new biobased products, conducted technical-economic analysis, and integrated project data into blockchain and digital twin systems. We have developed mathematical models for curing ham and storing fruit, created logistics optimization strategies, enhanced productivity and energy efficiency, and integrated models into the project’s digital twin system. We have successfully implemented a Blockchain network for supply chain traceability, completed requirement and use case definition, analyzed and implemented the blockchain, and developed a demonstrator platform for meat and fruit value chains. Once operationalized the data lake for centralized management, we are currently testing an advanced Digital Twin prototype, and initiated re-engineering efforts.

What innovative technologies or methods are you most excited about within your project?

Probably, the piece of technology that has a most direct, short term and best economic contribution to food business is artificial intelligence-powered vision. Imagine an industry that raises its own pigs in 80 fattening farms with about 200,000 pigs carefully fed and raised until they reach approximately 120kg. How would you know that 200,000 pigs have reached that size? Weighing one by one on a scale and spraying markings to show their status is NOT an option. If it took 3 minutes to weigh each pig, it would take 416 days, that is, more than a year, in 3 shifts of 8 hours. And that’s only to weigh them once during their lives. Today this is done by a qualified operator who chooses and marks the pigs after a VISUAL evaluation. Therefore, the variability of the product is large and the weight of the shoulders or legs varies significantly. Therefore the resulting products cure differently, because they depend on the size. Artificial vision using simple cameras on mobile phones are giving us an accurate weight with just 3.6% error, lets us monitor the growth with any periodicity (daily, weekly) to reach that 120kg goal (no more, no less) while also real-time spotting illness (associated to lower growth rates). Not only you have healthier animals, but more consistent leg and shoulder sizes, resulting in a more homogeneous curing process along the year and across multiple farms.

What advice would you give to other innovators looking to make an impact in the agricultural / food sector through digital technologies?

You may remember this slogan from a tire brand that was very popular in 1995 and featured Olympic medalist Carl Lewis known for his 100m world records wearing HEELS. The idea was simple: a car can be very powerful, but without good tires, that power cannot be controlled. The same thing happens with digital transformation: the theoretical potential is enormous, but without practical applications grounded in a concrete reality and generating specific benefits in exchange for a cost, that potential is useless. That’s my best advice -offer something that is practical, that gives short term, tangible benefits easily perceived at an affordable investment cost. The business is in maintenance, support, upgrades, expansion, performance. But is the entry barrier what needs to be overcome first.

An initial version of this article was published on 13/11/2024 on Synergy Portal under the title Synergy Days 2024 projects: BBTWINS. This version has been slightly modified to enhance clarity. All views expressed are those of the authors and may not reflect the positions of the rest of the project consortium.